Making money

Expert reviewers

Essentials

- Australia has one of the lowest rates of money counterfeiting in the world.

- Innovative science is behind many of the security features of Australian money.

- The invention and introduction of polymer banknotes was a major breakthrough in increasing the security of Australian money.

- The most recent Australian polymer banknotes also include a number of security devices to prevent counterfeiting.

Bad news for buskers and bucket-rattling charity collectors in animal onesies: cash is on the way out.

Now that we can wave a credit card to pay for a coffee, settle our bills electronically and make regular deposits to our favourite charity via direct debit, it seems we’re well on the way to a cashless society.

Or are we?

While there’s undeniably been a move towards electronic payment methods, the demand for cash continues to be strong. At March 2017, there were around 1.5 billion banknotes in circulation in Australia, and the number of banknotes being issued had grown at about 6 per cent per year for the last decade, peaking at times like Christmas and Easter.

It seems the Reserve Bank of Australia, for one, is pretty confident that ‘real’, physical money is sticking around for some time yet. The RBA has begun developing and issuing a new style of Australian banknote, starting in 2016 with the release of a revamped five-dollar note. There’s always plenty of discussion, and sometimes controversy, about the design and appearance of a new banknote, so the behind-the-scenes science and innovation can sometimes play second fiddle. In the case of the polymer banknote, it’s a uniquely Australian story.

Plastic cash

If you’ve been keeping up with the news, you’ll know that Britain, too, recently released a new fiver. The new polymer banknote was issued in September 2016, with a 10-pound note due to be released in 2017 and a 20-pound note in 2020. They’re just the latest to switch to plastic cash: polymer banknotes are now used in many countries across the world.

While the Brits have stuck with their pound, it’s been five decades since Australia gave it the flick. When Australia switched to dollars in 1966, its new banknotes had a number of security features designed to deter counterfeiters. Printed on quality paper, they included a watermark and intaglio (raised) printing, as well as state-of-the-art metal threads. Yet, within a year, over $100,000 worth of forged $10 notes had been collected by authorities, with over 1,500 forgeries passed in the state of Victoria alone.

In 1967, the Governor of the Reserve Bank of Australia approached senior Australian scientists, including some at CSIRO, to help develop a more secure banknote. It was to be the beginning of a decades-long journey, resulting in the release, in 1988, of Australia’s first polymer banknote.

Not everyone was enamoured with the idea of plastic cash. Indeed, while the science was up to scratch relatively quickly, with technical problems resolved within 10 years of beginning research, it took a further decade until the banking industry accepted and released the revolutionary new notes. One perception was that plastic looked ‘cheap’ and therefore not suited for use in the nation’s official currency. In the end, a series of ‘blind feel’ tests convinced the doubters.

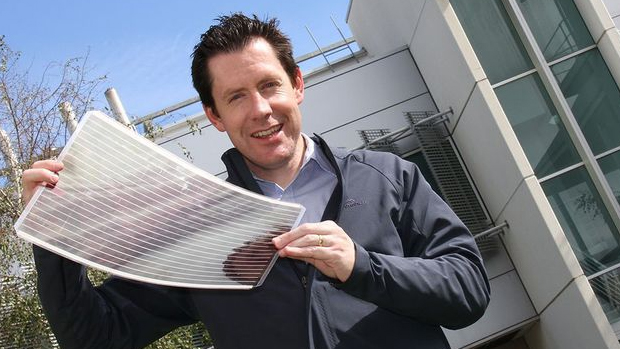

But the invention of a unique polymer substrate (as well as a number of other security devices) put science squarely at the centre of currency production—making forgery a more difficult prospect. To make a passable fake note, forgers would need to know about polymer properties, replication techniques and the chemistry and physics behind optically variable devices.

A unique polymer substrate

If you’re thinking a potential counterfeiter need only get their hands on a good roll of plastic book-covering, think again. The polymer substrate used for Australian banknotes is a unique polypropylene material—it’s produced using specialised technology and isn’t commercially available.

The substrate contains several film layers which are created using a ‘bubble’ process. Clear plastic beads are melted down and blown into a large bubble. During this process the film is stretched in both length and width to orientate the polymer molecules. The walls of the bubble are then pressed together and cooled, resulting in a clear polymer film. This base film is known as biaxally oriented polypropylene (BOPP), and has uniform tensile strength both horizontally and laterally.

The use of a clear polymer base also enables the inclusion in the banknote of a see-through window or windows. These are very difficult to counterfeit. Australia’s banknotes begin as a large roll of clear material onto which inks are applied, leaving the window clear. Each denomination of the existing series of Australian banknotes has a small, clear window. The new $5 note released in 2016 also has a clear window which runs the full height of the note and a third window in the shape of a bird.

Polymer science also comes to the rescue in tackling the thorny issue of the banknote’s feel. Initial concerns that banknotes would feel ‘plasticy’ were addressed by coating notes in a special polymer varnish. The chemistry of the varnish was controlled by varying its hydrophobic/hydrophilic ratios (that is, the tendency of the material to repel or bond with water molecules), while its physics were controlled by adding fine silica, giving the note a less slippery feel.

If you run your finger over an Australian banknote, you’ll also notice that it’s not completely smooth: the printing is raised up slightly from the surface. This is the result of what’s known as intaglio printing. Metal plates are deeply engraved with a design (say, the portrait of ex-convict Mary Reibey on the Australian twenty) and ink is applied to the plates. The ink is transferred to the sheets of polymer film under pressure, leaving a raised print.

Now you see it: optically variable devices

Australia’s commemorative ten-dollar note released in 1988 was the first polymer banknote in the world to include another difficult-to-forge security measure: an optically variable device, or OVD. An OVD is an image that changes appearance when the angle at which it’s viewed is changed. In the case of the 1988 note, the OVD was an image of Captain Cook that moved when tilted. Because OVDs change depending on the angle at which they’re viewed, and a copier or scanner can only copy a document at one angle, they can’t be effectively counterfeited by being scanned or copied.

Optically variable devices depend on the diffraction of light. Diffraction is where a light wave encounters an obstacle, creating a particular effect. To make the optically variable Captain Cook, a device known as a diffraction grating was used. This is a pattern of extremely small lines which are coated with a thin film of a reflecting material such as aluminium. When light hits the pattern, it is split into many beams travelling in different directions, creating a rainbow of different colours. It’s a similar effect to what you may have seen when light hits a CD, throwing a rainbow of coloured lights onto the wall.

After this initial venture into the use of OVDs, it was decided not to include them in Australia’s banknotes—not only were they very expensive to make, the unique polymer material and clear window were to prove sufficiently effective against counterfeiters. But in the new Australian polymer banknotes OVDs have made a reappearance. Several of these devices appear on the new, full-length clear window. They rely on materials such as foils which reflect light at different wavelengths depending on the angle at which they’re viewed. Optically variable inks, for instance, which contain pigments that reflect various wavelengths in white light differently depending on the angle at which the light strikes the surface, are used to create a ‘rolling colour’ effect.

Another feature on the new banknotes which relies on the properties of light is an embossed transitory image in the smaller clear window. Like the raised print on the note, this is created by intaglio printing—but without the ink. The engraved printing plates are left uninked, giving an embossed effect when the feature is ‘printed’ at high pressure onto the banknote. The image is made up of small lines, which creates a transitory effect—that is, the image can be viewed in transmission (when looking through the window) as well as in reflection.

If you happen to have a UV light handy, you may be able to see some further features not visible in normal daylight: a bird, the serial number and the year of print all fluoresce under a UV backlight with a wavelength around 365 nm. Fluorescent materials produce light when the atoms in them become excited, releasing energy in the form of light as they return to normal. These usually-invisible features on Australia’s new banknotes are created using fluorescent inks—they contain chemicals which absorb energy from UV light, become excited, and release energy as light, producing the ‘glow’ you’ll see if you put them under a UV lamp.

Over the rainbow

While finding the pot of gold at the end of the rainbow may be the stuff of fairy tales, with their colourful and distinctive plastic cash Australians carry their own pocket-sized rainbow wherever they go. Though we may one day see the demise of physical money, the science behind the invention of the polymer banknote will no doubt persist, already finding new life in the burgeoning field of flexible electronics.